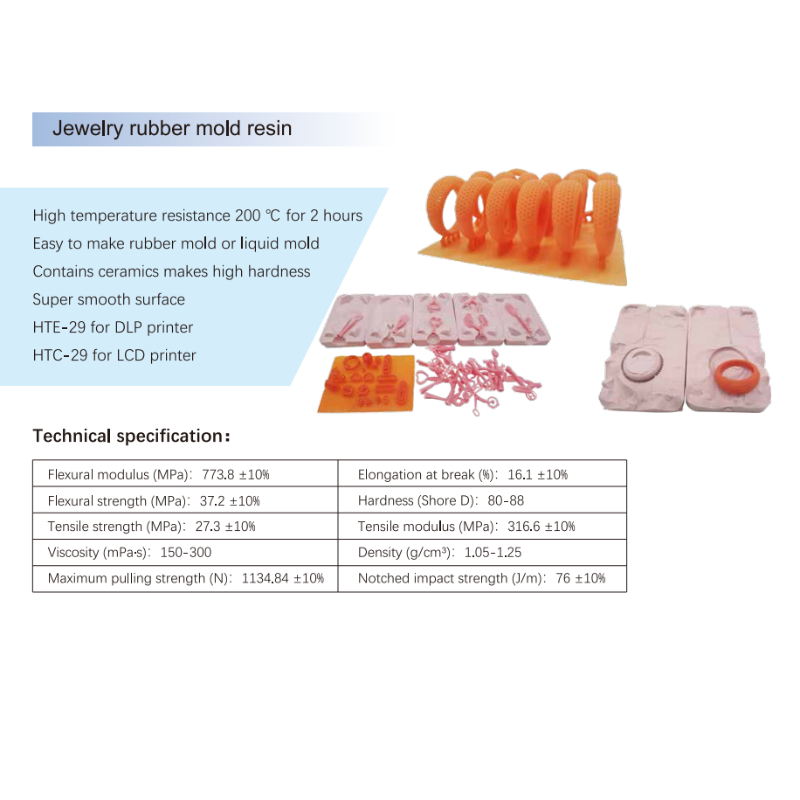

Product Advantage:

- High precision with super smooth surface

- Anti- high temperature 200℃ for 2 hours

- Super hardness(Shore D): 88D

- East to make rubber or silicone mould

- Non VOC, RoHS Reach En71-3 certificated

- Compatible for most 3D printer

Technical specification:

| Flexural modulus:773.8 Mpa ±10% | Elongation at break:16.1% ±10% |

| Flexural strength :37.2 MPa ±10% | Hardness(Shore D):80-88 D |

| Tensile strength:27.3 MPa ±10% | Viscosity:150-300 MPa·s |

| Tensile modulus:316.6 MPa ±10% | Density:1.05—1.25 g/cm3 |

| maximum pulling force: 1134.84 N ±10% | Notched impact strength: 76 J/m ±10% |

| Yield point elongation:5.3% ±10% |

- Testing room temperature:23℃±2℃ Testing room humidity :50%RH±5%RH

- Testing standard of test strip: ASTM

- Post curing: test strip in water for 1 mins post curing with 200mw/cm²405nm.

Printing parameter :

- For LCD printer with RGB screen:

e.g. elegoo mars or photo s base 50s, each layer 8s, layer height 50 micron. - For LCD printer with monochrome screen:

e.g. satori base 50s, each layer 3s, layer height 50 micron. - For DLP printer with projector:

Bottom 15s and each layer 1-5s.

e.g. hunter base 15s, each layer 4s, layer height 50 micron. - The exposure time should be adjusted according to printer light energy, layer thickness and model structure.

Cleaning and post-curing:

- Step1, Spray with Isopropanol, then blow resin away with cool wind.

- Step2, Prepare two containers with Isopropanol (alcohol> 95%), and place the jobs into the first container and slightly shake it, then soak in the second container for about 1 minute (dental resin should not exceed 30 seconds).

- Step3, Flush with water before dry it, do make it sure it ‘s 100% dried as residuary alcohol may cause white spot or crack on jobs.

NOTE:

- Do not use ultrasonic for cleaning, especially for casting resin.

- Dental resin jobs are recommended to be cleaned before takeoff from the platform to avoid deformation.

Post-curing:

- The curing time is proportional to the volume of the work piece and inversely proportional to the optical power of the curing chamber. Example: 150 watt LED curing box, jewelry jobs is recommended to be cured with soaking in water for 20-30 minutes.

- The post-cure time of D casting resin, D-Non-casting resin and jewelry mold resin shall not more than 5 minutes.

- Work-pieces should be in the water during post-curing to prevent deformation especially for dental and jewelry.

- Don’t forget to use cool air to dry it after post-curing.

Warning:

- This material should not be in contact with eyes, skin or clothing, and should not be tasted or eaten.

- If you accidentally touch your eyes or skin, immediately rinse with water for about 20 minutes and seek medical advice if necessary.

- Please pay attention to air circulation and take protective measures when using. Wash thoroughly after handling.

- The product is in a liquid state with a slight odor. Wear a mask and gloves.

- The product should be stored in a sealed container. After use, it should be filtered and keep back in bottle on time and placed in a dry and well ventilated place. It should not be exposed to sunlight.

- Shake well before use, and leave it for 30 minutes to eliminate air bubbles that generated during the shaking process.

- The ambient temperature is recommended to be controlled at 25-30 degrees Celsius, and during the printing should avoid any lights.

- Dispose of waste in accordance with local environmental regulations.

- Storage environment: Store in cool and dry place, and avoid sunlight, recommended temperature at 25-30 degrees Celsius.